PRODUCT

Pressure/Vacuum Relief Valves (Breather Valves and Conservation Vents)

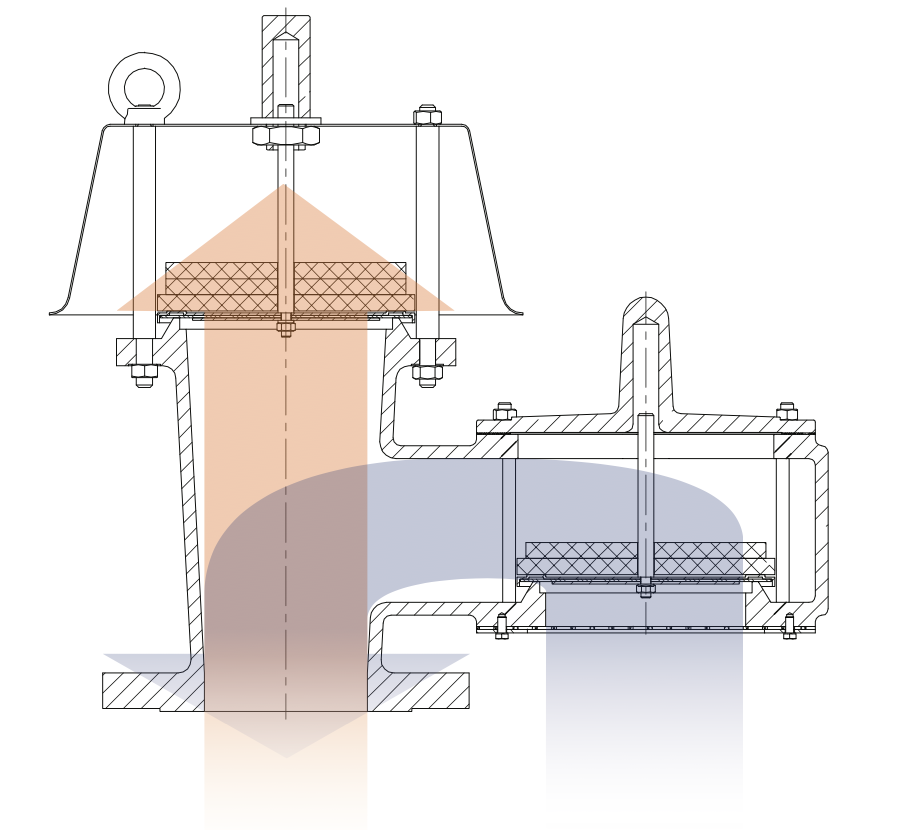

Direct acting Pressure/Vacuum Relief Valves are low pressure devices specifically designed to protect tanks, process systems and equipment from excessive pressure and vacuum.

In addition to providing a primary layer of protection for tanks and process systems, Pressure/Vacuum Relief Valves also minimize emission losses of gases or vapors, thus protecting the environment and providing significant financial savings.

Pressure and Vacuum Relief Valves are also commonly known as breather valves or conservation vents.

Description

Features and Benefits

• Pressure/Vacuum Relief Valves provide high flow capacity from a compact valve size

• Wide range of pressure and vacuum settings to provide maximum tank protection whilst ensuring minimum gas loss

• Designed and manufactured to API Std 2000:2014/ EN ISO 28300:2016

• Superior sealing meets the stringent demands of emission control regulations

• Exceeds seat leakage requirements of API Std 2000:2014 or EN ISO 28300:2016

• No measurable leakage below 90% of the set pressures, less than 1 SCFH (0.03 m3/h) at 90% of the set pressure

• Low leakage minimizes evaporation loss

• Economic savings due to reduced product loss

• Alternative connection types available on request

• Proximity switches available on request

• Valve sizing service provides optimum valve performance and cost effective technical specification

• Elmac technical support

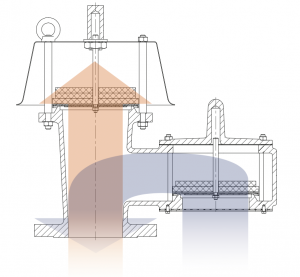

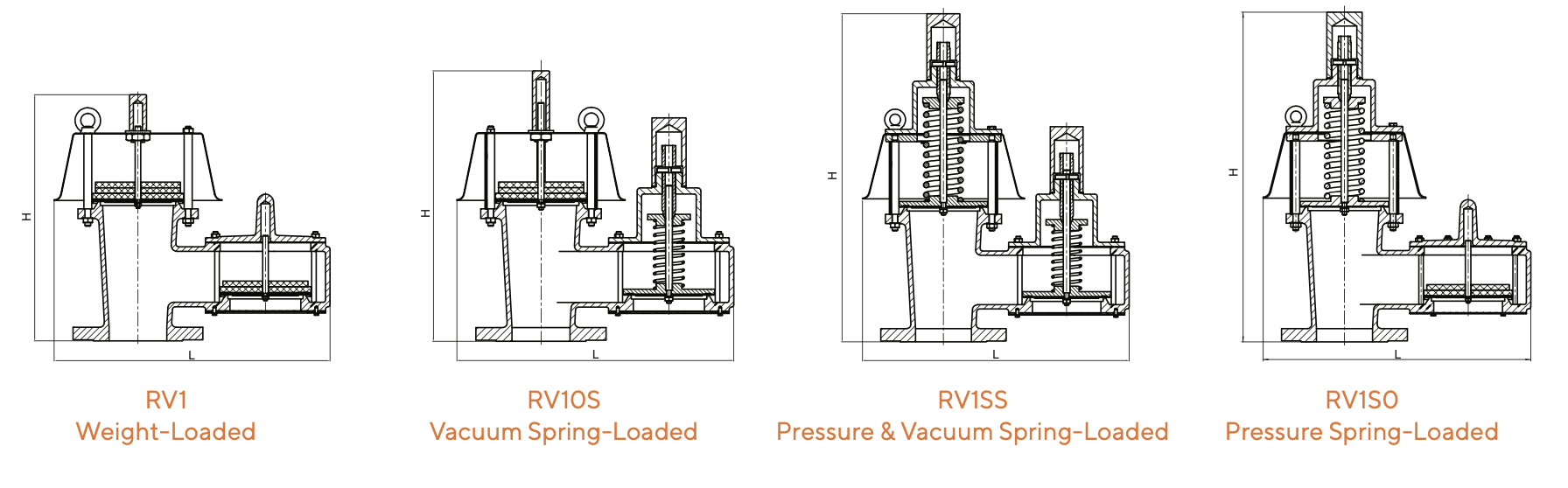

Pressure & Vacuum to Atmosphere

Series RV1 Valves which are vented to atmosphere, are designed to protect your tank from damage created by over-pressure or excessive vacuum. Costly product evaporation losses due to normal tank ‘breathing’ are greatly reduced.

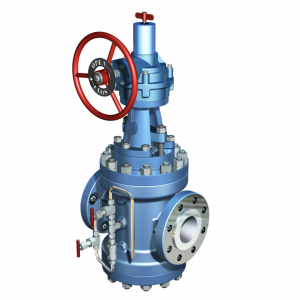

Pressure & Vacuum to Piped Away (Closed Line)

Series RV2 Valves are used for pressure and vacuum relief where vapors must be piped away (Closed Line). Special pallets with air- cushion sealing virtually eliminate the intake of air and the escape of vapors during normal breathing, thus reducing the loss of product.

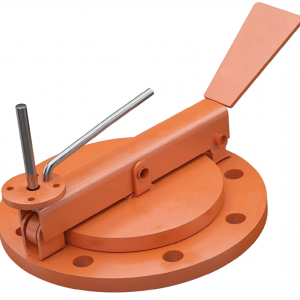

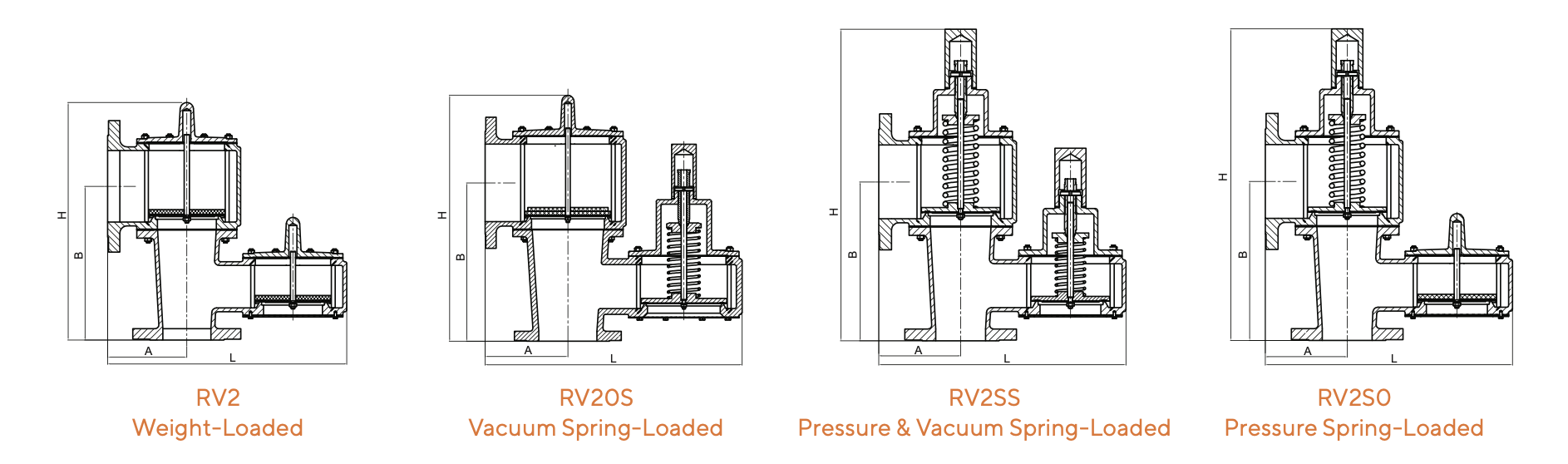

Pressure-only Relief Valves

Series PR1 and PR2 Valves are for use where pressure relief is required. The vapors relieved can be either vented to atmosphere or piped away. In order to avoid tank damage, spring or weight-loaded pallets can be selected for different set pressures.

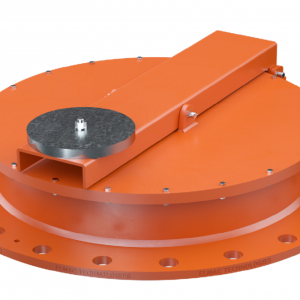

Vacuum-only Relief Valves

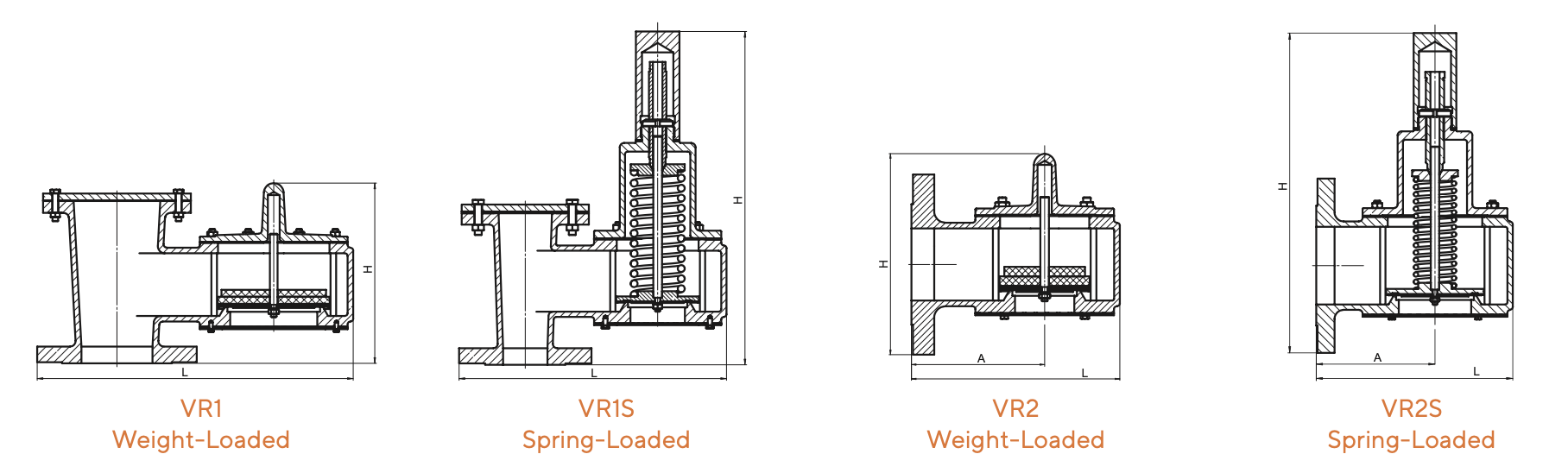

Series VR1 and VR2 Valves are for use where vacuum relief is required. Intake relief is from the atmosphere and achieved by using a spring or weight-loaded pallet to achieve the required set pressure. Can be installed on top of the tank with bottom flanged valve or on the side walls of the tank with side flanged valves.

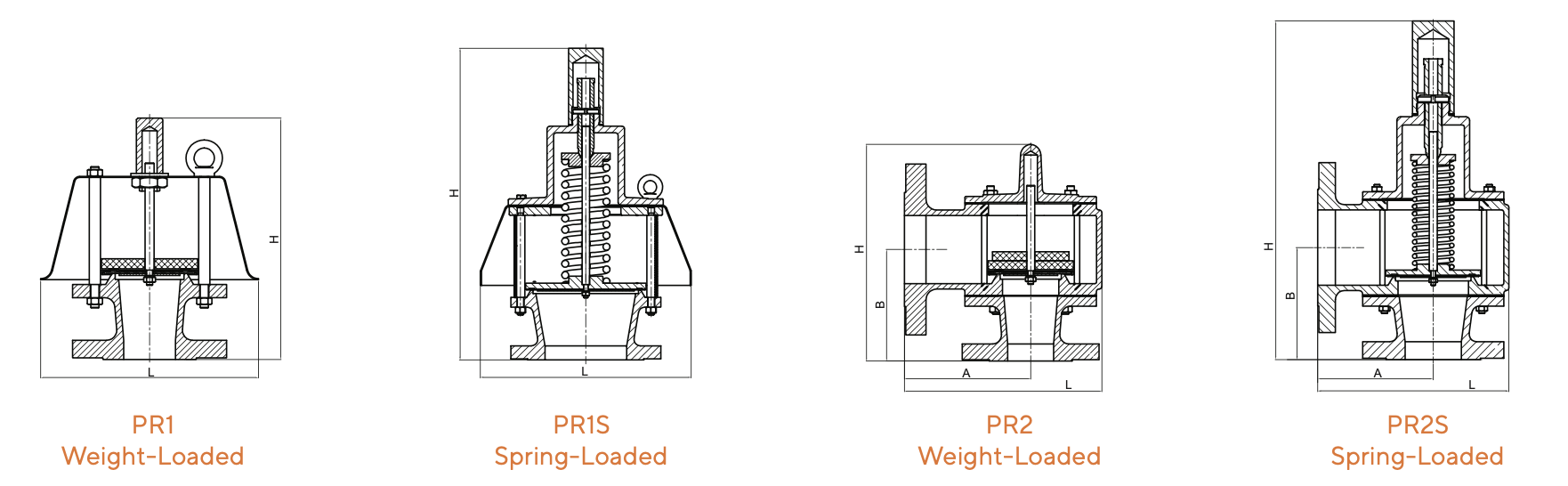

‘Cowhorn’ Arrangement

Pressure/Vacuum Relief Valves and/ or Flame Arresters in the ‘Cowhorn’ Arrangement

The Elmac Technologies® ‘Cowhorn’ Arrangement includes twin sets of pressure relief valves and/or flame arresters. It is intended for use on digesters where overpressure and explosion protection is required.

By utilizing this duty/standby arrangement, one set of flame arrester and valve combination can be maintained whilst the other is in service.

Features and Benefits

• Suitable for Biogas application

• Sizes and materials to suit a wide range of applications

• High flow capacity

• Easy inspection and maintenance

• ATEX approved • Isolation valve allows switch-over function

• Pressure/Vacuum relief valves can be set up to 0.4barg depending on size