PRODUCT

High Performance in Waste Water Pumping

High Performance in Waste Water Pumping

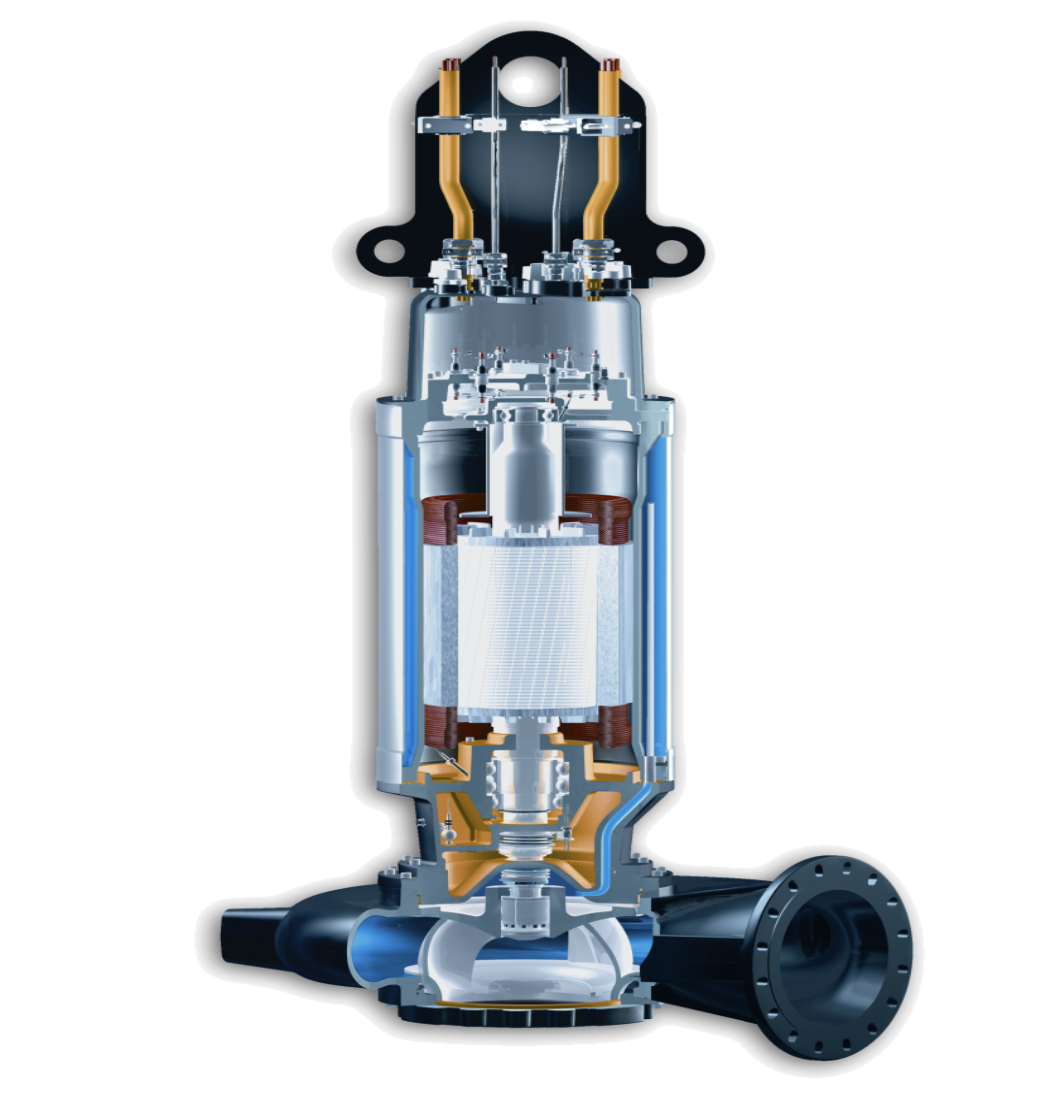

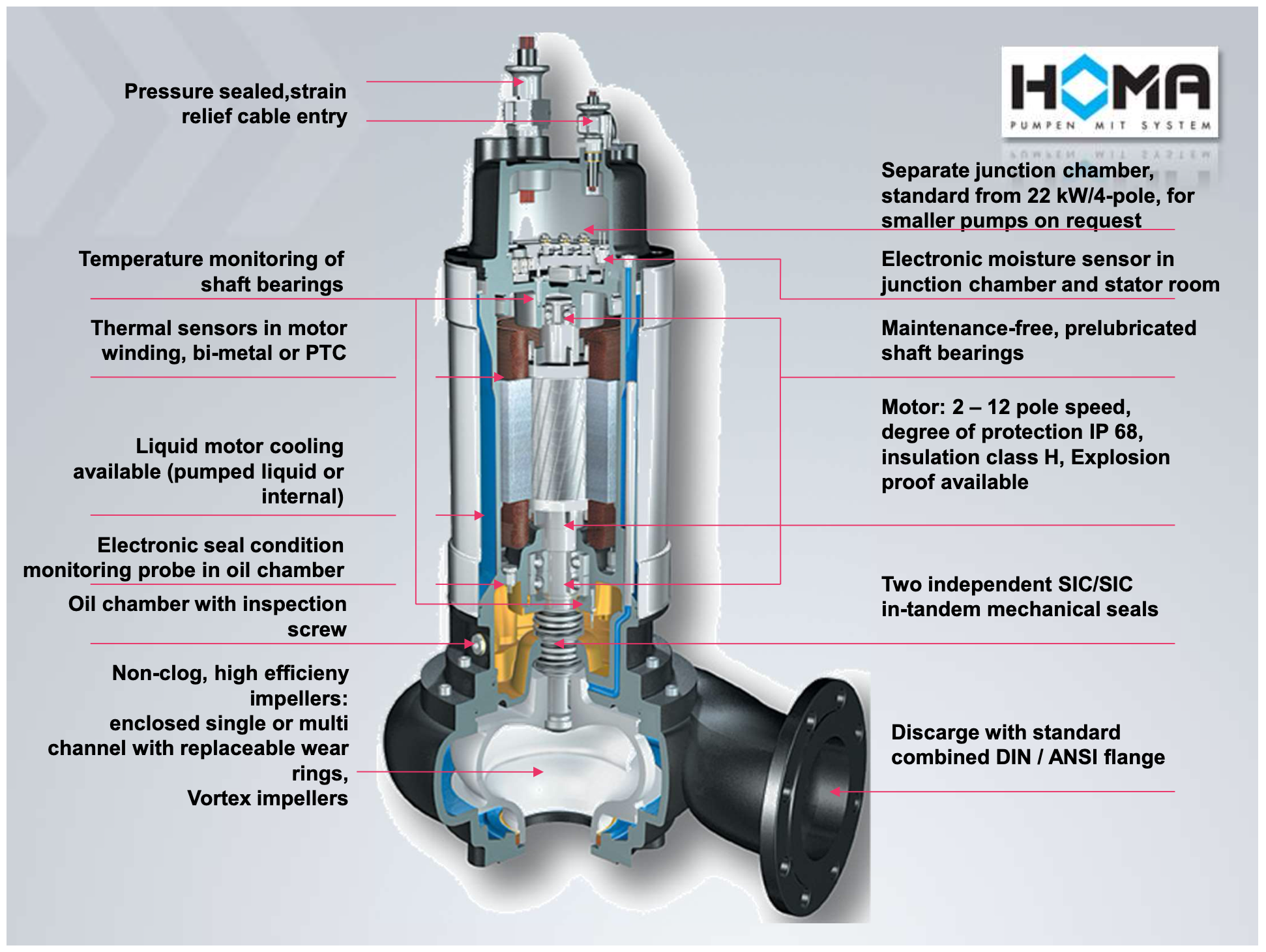

HOMA submersible waste water and sewage pumps operate worldwide in numerous kinds of domestic, municipal and industrial applications. Decades of experience in the design and manufacturing of submersible pumps plus uncompromising attention to quality in every detail and strict monitoring of production quality ensure the utmost reliability and long service life of all HOMA products.

Description

-Submersible motors from 0,3 kW to 500 kW

-All motors from 1,5 kW available with liquid cooling system for wet or dry pit installation

-All motors for frequency converter operation

-All motors available in Explosion proof to European and US standards

-Hydraulic performance Hmax up to 90 m and

Qmax up to 6000 m3/h

-Channel or Vortex impeller hydraulics up to 200 mm solid size and DN 500 discharge

-Submersible Propeller Pump range

-Full range of submersible Grinder pumps

-Mixers with direct or transmission propeller drive

-Various material options: Hard Cast Iron, GGG40, Bronze, Stainless steel, Super Duplex for customized solutions

Flexible system-components for problem-free installation HOMA combines efficiency, safety, high quality and robust design with a flexibility that allows the individual optimization of every project realization:

Pumps for various types of application and installation, a complete program of installation equipment including pipes, valves, pump pits from concrete or composite materials, electric control and monitoring systems. With this range HOMA can provide a tailor-made solution for every waste water pumping application.

The reliability of fully automatic operation HOMA waste water pumping stations feature fully automatic control and monitoring. Reliable liquid level control systems of various types (float switch, pneumatic, ultrasound or electronic systems) are available to secure reliable pump operation at minimum energy consumption. All possible fault factors like shaft seal condition, temperatures, moisture or power supply can be automatically monitored and transferred to various alarm systems.

Production:

Submersible Pumps up to DN 500

Motor Designs – Waste water pump without cooling jacket

Waste water pump with cooling jacket (open or closed loop)